#1 Project Requirements

When considering purchasing a sonic drilling rig, the primary step is to thoroughly understand the specific requirements of the project. This includes considering the type of geological formations, the depth needed to reach, and the borehole diameter required. It’s essential to consider the specific nature of the work, whether it’s environmental investigations, geotechnical drilling, or mineral exploration.

#2 Rig Size and Power

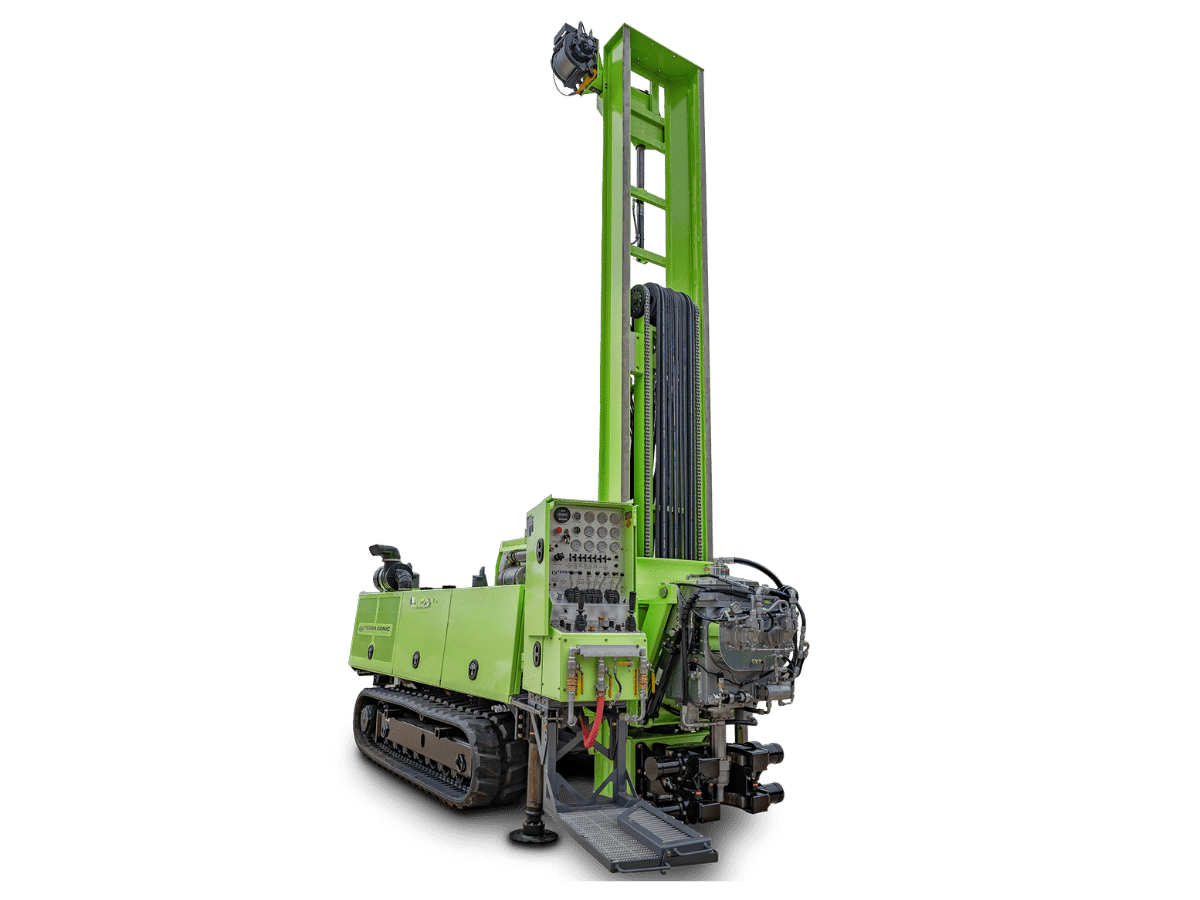

Size and power are significant factors to consider when investing in a sonic drilling rig. For large-scale, extensive projects that require deep drilling, larger rigs with robust power may be the best fit. On the other hand, if the operations are situated in confined spaces or urban environments where access is limited, smaller, compact rigs might be a better choice.

#3 Training and Technical Support

Technical support and training are critical considerations when investing in a sonic drilling rig. Look for manufacturers that provide comprehensive training to operators to ensure they can operate the rigs efficiently and safely. Additionally, ensure that the manufacturer offers solid post-purchase support, including maintenance and repair services.

#4 Long-Term Costs

While the initial cost of a sonic drilling rig might seem steep, it’s crucial to consider the long-term implications. Sonic drilling rigs offer increased efficiency and faster drilling rates, which can lead to significant cost savings over time. Additionally, the durability and lower maintenance needs of these rigs can also contribute to cost reductions in the long run.

#5 Manufacturer Reputation

The reputation of the sonic drill rig manufacturers should not be overlooked. Like Drillrigy, a reputable manufacturer should provide high-quality equipment that is reliable and durable. Look for manufacturers known for their commitment to innovation, customer support, and quality control. Online reviews and industry recommendations can provide valuable insights into a manufacturer’s reputation.